So, without any warranty and trusting that you are able enough to carry out this procedure yourself and safely, here is how to save yourself a small packet on changing the electric motor.

First of all, pull the flexible hose out of its socket where it goes into the main cyclone First of all, pull the flexible hose out of its socket where it goes into the main cyclone

|

Next, turn it onto its side and on the support bracket, press the little lever - the end furthest from the body of the cleaner - pulling the bracket out. Next, turn it onto its side and on the support bracket, press the little lever - the end furthest from the body of the cleaner - pulling the bracket out.

Put the hose assembly to one side. |

Next, open the top... Next, open the top... |

...remove the cyclone... ...remove the cyclone... |

...and take out the filter, putting them to one side. ...and take out the filter, putting them to one side. |

Next, using a blunt knife (or other flat, but not sharp, object), gently force the hinge open. You can see that the amount you have to bend the hinge is only small and remember - somebody in a factory assembled it just by pushing it together so it must be able to bend that much without breaking. Next, using a blunt knife (or other flat, but not sharp, object), gently force the hinge open. You can see that the amount you have to bend the hinge is only small and remember - somebody in a factory assembled it just by pushing it together so it must be able to bend that much without breaking. |

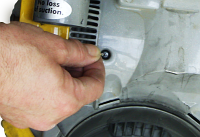

Now, remove the air guide that sits underneath the clear cyclone. Release it by pressing the two tabs - one of which you can see by my index finger. Once these are freed, just pull it out. Now, remove the air guide that sits underneath the clear cyclone. Release it by pressing the two tabs - one of which you can see by my index finger. Once these are freed, just pull it out. |

Next, lift out the filter that sits underneath the air guide. Dyson might not have a bag across which air pressure can be lost but they do have plenty of filters. Next, lift out the filter that sits underneath the air guide. Dyson might not have a bag across which air pressure can be lost but they do have plenty of filters. |

Next, you need to take off the wheels - this is because there are screws under there that hold the two parts of the body together. Basically, all you do is put something between the body and the wheel and pull the wheel off. I used a screwdriver this time and it didn't seem to do any harm. Next, you need to take off the wheels - this is because there are screws under there that hold the two parts of the body together. Basically, all you do is put something between the body and the wheel and pull the wheel off. I used a screwdriver this time and it didn't seem to do any harm.

I have received several emails informing me that on some models, there is a plastic insert at the centre of each wheel that needs removing before the wheel can be taken off but there was none on mine. If you have the plastic insert, I am advised that it can be removed by drilling a small hole in the plug which makes it more flexible - this also allows for somewhere to insert a screwdriver into the plug to act as a lever should this become necessary. |

Now unscrew the four screws that were hidden behind the wheels. These have hexagonal sockets in them so you can use one of the specialised screwdrivers for this purpose but, if you want, you can use an Allen Key like I have here. Now unscrew the four screws that were hidden behind the wheels. These have hexagonal sockets in them so you can use one of the specialised screwdrivers for this purpose but, if you want, you can use an Allen Key like I have here. |

Now, remove the screw that is in the middle. This one is quite deep but it is not impossible to get to. Now, remove the screw that is in the middle. This one is quite deep but it is not impossible to get to. |

Now take off the casing - you might find that the cable drum wants to come off as well so unclip the two connectors that run across the middle and remove it, along with the casing. Now take off the casing - you might find that the cable drum wants to come off as well so unclip the two connectors that run across the middle and remove it, along with the casing. |

This is what it should look like now. This is what it should look like now.At this point, just check that your mains lead works - if it is that that is at fault, chop off the plug and around 6 inches (15cm) of cable and check for continuity again. If you have it, you probably just need to repace the plug and you've saved yourself the cost of buying a new motor (if you don't, try chopping off another six inches and trying again). |

Assuming that the mains lead turned out all right, pull the halves apart like so. Assuming that the mains lead turned out all right, pull the halves apart like so. |

And, this is what it looks like. And, this is what it looks like. |

Now, you have to take off the end so that you can get to the motor. The end is held in place with four little latches and bending them slightly - testing them one at a time - will allow you to take out the end. Now, you have to take off the end so that you can get to the motor. The end is held in place with four little latches and bending them slightly - testing them one at a time - will allow you to take out the end. |

And this is what is underneath. It is a large, circular rubber contruction that seals around the edge, on a metal surface below and on the surface above. Lift this out and put it to one side. And this is what is underneath. It is a large, circular rubber contruction that seals around the edge, on a metal surface below and on the surface above. Lift this out and put it to one side. |

Now, you can see what it seals against. This is the air intake end of the motor and inside the hole, you can see the end of the motor shaft and the inside of the impellar. Now, you can see what it seals against. This is the air intake end of the motor and inside the hole, you can see the end of the motor shaft and the inside of the impellar. |

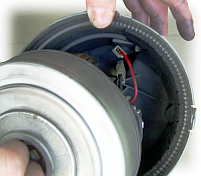

When you pull it out, you can see that the motor is connected with similar connectors to the leads on the outside of this plastic cylinder. However, the leads are short - there is a valid reason for this and that is that if they were much longer, they would catch in the motor. When you pull it out, you can see that the motor is connected with similar connectors to the leads on the outside of this plastic cylinder. However, the leads are short - there is a valid reason for this and that is that if they were much longer, they would catch in the motor. |

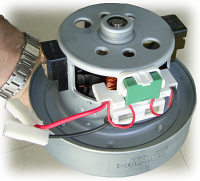

And this is it. Make a note of the number that you find on the side. There are two types of motor for the DC05 and you need the right one. Note that there is a rubber moulding on the top of this - take that off because you will need it. And this is it. Make a note of the number that you find on the side. There are two types of motor for the DC05 and you need the right one. Note that there is a rubber moulding on the top of this - take that off because you will need it. |

This is what the new cable drum box looks like (so that you know that you've been sent the right thing). The Dyson (manufacturer's) part number is 911933-01 - "JDK YV-2100-1 240V MOTOR" for Dyson DC05 (£49.99). This is what the new cable drum box looks like (so that you know that you've been sent the right thing). The Dyson (manufacturer's) part number is 911933-01 - "JDK YV-2100-1 240V MOTOR" for Dyson DC05 (£49.99). |

And this is the new one. This is a breath of fresh air compared to the old one. Again, note the short leads. Also, note that there is no rubber moulding on this. And this is the new one. This is a breath of fresh air compared to the old one. Again, note the short leads. Also, note that there is no rubber moulding on this. |

This is what the new moulding in the middle looks like. This is what the new moulding in the middle looks like. |

And this is what the pins on the inside of the cylinder look like. You need to slide the moulding in place so that it can take the end of the motor. And this is what the pins on the inside of the cylinder look like. You need to slide the moulding in place so that it can take the end of the motor. |

And this is it in the right place. (Don't bother trying to put it on the motor first because when you push the motor into the cylinder, it most likely won't align properly.) And this is it in the right place. (Don't bother trying to put it on the motor first because when you push the motor into the cylinder, it most likely won't align properly.) |

This is how it should line up. This is how it should line up. |

This is the only really tricky part of the whole assembly. You need to plug the wires into their respective sockets which means bringing the motor up close to the plastic housing. This doesn't leave a lot of space to get your fingers in. I presume that at the factory, either they use women with very slim hands to do this or they use a machine. Once it is in place, you can push the motor into the plastic housing and it will locate positively. This is the only really tricky part of the whole assembly. You need to plug the wires into their respective sockets which means bringing the motor up close to the plastic housing. This doesn't leave a lot of space to get your fingers in. I presume that at the factory, either they use women with very slim hands to do this or they use a machine. Once it is in place, you can push the motor into the plastic housing and it will locate positively. |

Next, you need to insert the rubber gasket that holds the motor in place and forms various seals. This just pushes into lace but make sure that it is all of the way in and that the motor is located centrally. Next, you need to insert the rubber gasket that holds the motor in place and forms various seals. This just pushes into lace but make sure that it is all of the way in and that the motor is located centrally. |

Now, put the housing onto the end. This can only go on one way because of the tiny castellations around the rim. Now, put the housing onto the end. This can only go on one way because of the tiny castellations around the rim. |

Slot the motor unit into the frame and rotate it down - doing the opposite of what you did earlier to get it out. Slot the motor unit into the frame and rotate it down - doing the opposite of what you did earlier to get it out. |

Put the cable drum back in place, making sure that the cable release is aligned properly. Plug in the blue and brown wires and push them into the comb on the body. Next, swing the lower part of the outer casing into place. Put the cable drum back in place, making sure that the cable release is aligned properly. Plug in the blue and brown wires and push them into the comb on the body. Next, swing the lower part of the outer casing into place.

Turn the machine over so that it is the right way up and put the four screws that would be hidden by the wheels into their holes along with the fifth screw in the middle of the body, screwing them down but not tightly. |

Finish tightening the five screws therefore making sure that the body is not put under undue stress. Finish tightening the five screws therefore making sure that the body is not put under undue stress. |

Next, put the filter in place with the large gap at the bottom. Next, put the filter in place with the large gap at the bottom. |

Then, put the air duct in place, making sure that the two clips hold it. Then, put the air duct in place, making sure that the two clips hold it. |

After that, put the end on, insert the green filter and put the cylinder in place. After that, put the end on, insert the green filter and put the cylinder in place. |

Finally, put the wheels on and re-attach the flexible hose and you are ready. Finally, put the wheels on and re-attach the flexible hose and you are ready. |

|

| Copyright (c)2007 Paul Grosse. All Rights Reserved |