|

Recovery systems -

Nose Separates at Apogee

This is the

simplest method of deploying a parachute or streamer.

Unfortunately, it is also has a reputation for not being

particularly reliable unless you are careful to make it

so. This will be discussed here. Mounting the nose with

parachute onto the rocket is exceptionally easy in the

field with this method.

Design

This device is designed to be a separate unit that can

be attached to any suitably sized bottle. It is made from

one standard 2 litre bottle and will house any of the

parachutes or streamers.

The parachute can be packed and the rocket mounted on

the launcher as two separate procedures as the parachute

is connected to the rocket via a bottle top which can be

simply screwed on at the right time.

Manufacture

All that you need to build this is . . .

- One 2 litre pop bottle;

- Some gaffer tape;

- A soldering iron;

- Some sand paper; and,

- A pair of scissors.

As

this procedure requires increased air pressure to

inside of the bottle, it must be done before any

cutting operations are performed on it. As

this procedure requires increased air pressure to

inside of the bottle, it must be done before any

cutting operations are performed on it.To

modify the nose cone (the bottom of a pop

bottle) in order to make is more

aerodynamically sound, you first of all need to

have the connector described on the connectors page.

Attach this to the bottle (as described on

that page) and pump up a fair pressure -

between 1 and 3 BarG.

Unscrew the pump, leaving the hose (with

its one-way valve) in place and start to

rotate the bottle, holding the nose (a)

approximately 9" above a gas ring (for

those without gas rings, I have seen a barbecue

mentioned as an alternative although I have not

used one myself). After a while, the plastic

will have softened sufficiently to form a

hemispherical shape by itself (b),

at which point, you should cool it down under a

cold tap or in a bowl of cold water.

Remember that unlike the body of the rocket,

this structure does not have to withstand any

extreme pressure.

|

Carefully Carefully

mark out two rings on the pop bottle (about 1

cm apart, near the bit where the sides become

parallel). I have found a convenient way of

doing this by trapping a felt tipped pen in a

drawer and then holding the bottle at either end

whilst rotating it. Cut along the lines with a

pair of scissors. You now have all of the bits

that you will need.

mark out two rings on the pop bottle (about 1

cm apart, near the bit where the sides become

parallel). I have found a convenient way of

doing this by trapping a felt tipped pen in a

drawer and then holding the bottle at either end

whilst rotating it. Cut along the lines with a

pair of scissors. You now have all of the bits

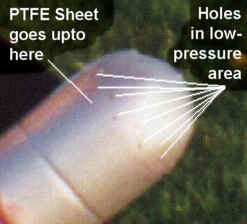

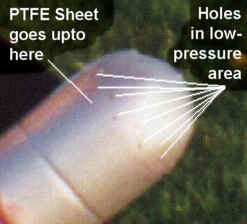

that you will need. Make a series of around 30

holes in the nose cone, on the straight portion

just where the curve of the nose finishes. There

is a low pressure area here and making around 30

holes in 2 lines around 1 cm apart will keep the

pressure inside the nose low enough to keep it on

the rocket until it gets to apogee. Note that the

PTFE sheet, if you are going to use one goes up

the inside almost as far as this but make sure

that it doesn't cover the holes.

|

|

Now cut the

ring and tape it so that there is about 1

cm of overlap. Tape this to the neck of

the bottle top as shown in the diagram on

the left. (I have found that in most

cases, this ring is not needed but you

can include it if you expect to have

problems with the nose falling off on the

launcher.) Then, using the soldering

iron, cut an inverted 'U' (as shown

in the picture on the left) thus

creating a tab. The position of this tab

should be such that the nose cone can

rest on the tab without having to be

forced into position - in other words,

the tab stops the nose from sliding back

over the rocket during thrust phase and

allows it to fall off at apogee.

Then, slide the tip of the soldering

iron across the base of the tab lightly

so as to soften the plastic at this point

(don't heat it up enough to cut or

melt the plastic) and then, while

flexible, bend out to around 30° from

the side (as shown in the diagram).

Allow it to cool in this position.

Repeat at equal intrvals so that you end

up with either 3 or 4 tabs making sure

that they are positioned acurately so

that the nose cone is both supported

evenly and is straight. If you put too

many tabs on, you run the risk of

increasing the pressure inside the nose

cone.

|

|

|

|

You now have the base unit for the nose cone.

Slide the base unit over the end of the bottle

and then tape it to the bottle, making sure that

the nose cone will sit straight on it.

Then, make a hole in the bottle top with the

soldering iron so that the elastic shock cord of

the parachute will go through it. Note that this

hole should only be large enough to take the cord

that you are going to use for the drogue chute -

during flight, this is a high pressure area and

if the hole is too large, it will allow air into

the nose cone which will cause early deployment.

Once you have packed your parachute, the job is

complete (see the photogaph at the bottom of

the page).

A circular parachute should be packed by

holding it by the centre in one hand whilst

holding the ring where the cords join either in

the other hand or under your foot. Make sure that

there are no tangles in the cords and then make

sure that the shroud has all of the loops of

farbic away from the axis (where the cords

should be). Now, gather up the shroud and

fold it into a three or four part zig-zag such

that the edge of the chute (where all of the

joints with cords are) protrudes a little.

The cords should be zig-zagged in the same way.

This means that the parachute occupies a minimum

volume and when the chute is deployed, there are

no tangles. If you were to scrunch the chute up,

there would be a distinct lack of space and if

you wound the cords around and around the folded

chute, it would never unwrap itself in time.

Using a zig-zag strategy means that the chute

acts like a spring when it is deployed.

Just add fins (see the aerodynamic

fins page for construction

details) and you have your rocket.

|

| Now all you

have to do is tie all of the bits

together in some sort of logical order

and fold and pack the cute correctly to

make sure that the parachute deploys at

the right time. Note

that by having a separate nose cone that

is secured to the base unit only by one

bottle top, it is possible to back the

parachutes into the nose cone, fill the

rocket and mount it on the launcher and

then take the nose cone, gently screw the

top onto the thread on the base unit (you

don't need to do this tightly as: it is

not going to get a chance to unscrew;

and, it only has to hold onto a hundred

grammes or so of rocket for a few seconds)

and put the nose cone in place.

Here are some different strategies:

|

|

As in the diagram

on the left, melt a hole in the

end of the nose cone and push the

drogue shock cord through it and

tie a knot to secure it. Pack the

main chute as described above,

then pack the drogue ensuring

that the drogue's chute will

deploy before the drogues strings

(this means that the drogue

will come out quicker). When

the nose cone separates, the

drogue deploys, pulling the nose

cone off the main chute and they

both float to the ground

separately.

As in the next

diagram, the drogue is tied to

the centre of the main chute

which is then secured to the nose

base unit using the bottle cap.

The nose cone itself is secured

via a short cord which is passed

through two holes melted in the

side of the nose cone (for

the sake of clarity, the diagram

shows this cord on the other side

- in reality it would be on the

same side as the main chute shock

cord) with a soldering iron

(make sure that you remove

any burrs with a sharp knife and

sand any rough bits). When

the nose cone separates, the

drogue deploys and drags the main

chute out of the nose cone and

they both float to the ground

together.

Another option is

to tie the drogue to the nose

cone (as in the first diagram)

and the main chute to the rocket

but to have a line that connects

the nose cone to one of the main

chute cords via a loose knot that

can slide up or down the main

chute cord. This line has to be

longer than the radius of the

main chute. When the nose cone

separates, the drogue deploys and

pulls the nose cone off the main

chute which then deploys. The two

float to the ground joined by the

line. The ony disadvantage this

has is that there is a greater

probability of the line snagging

the other chutes. An amount of

practice is needed to get the

packing right if you are going to

use this in a right first time

situation such as a science

olympiad.

|

|

|

|

One distict

improvement for this method is to allow

for the easy deployment of the main

chute. One serious problem is the

chute catching on any burrs on the nose

cone - simply cut off and sand any burrs

so that the chute will fall out freely.

Another serious problem is the amount

of force required to get the main chute

out. The easy solution is to sprinkle

talcum powder over the chutes and cords

and inside the nose cone - the talcum

powder acts as a dry lubricant.

One alternative

is to use a PTFE sheet inside the nose

cone. The sheet is cut so that it lines

the side of the nose cone (there is

no need to cover the end) so that

whereever the parachute needs to slide

across the inside of the nose cone, it

only comes into contact with the sheet.

These sheets are available in

supermarkets and are allegedly for lining

oven trays but their primary purpose of

making parachutes deploy easily is enough

to justify their existence.

An additional solution is to make the

nose tapered slightly - this has the

effect of making the sides of the nose

cone face the open end instead of the

other side. As a result of this and the

chute's own springiness, the chute is

pushed out to some extent.

To make the nose tapered, shrink it

slightly during the nose rounding stage (as

described on Body section of the 1½

litre 'Egglofter'

page).

|

|

|

|

So, to use this

device: So, to use this

device:

- Pack the chute(s) (according to your strategy) in

the nose cone USING PLENTY OF TALC or a PTFE

sheet and put it to one side;

- Fill the rocket with water and mount it on the

launcher;

- Lightly screw the chute shock cord bottle top

onto the nose base unit (there is no need to

make it tight);

- Pressurise; and,

- Release.

Note that the order of steps 1 and 2 can be reversed

without consequence.

For Talc assisted deployment, look at pictures with the

circular Bin-Liner

and Nylon

parachutes.

For PTFE assisted deployment, look at

some pictures of a 2

litre rocket.

Back to

the Water Rocket Recovery Systems Index Back to

the Water Rocket Recovery Systems Index

Back to the Water Rocket Index Back to the Water Rocket Index

|

|

As

this procedure requires increased air pressure to

inside of the bottle, it must be done before any

cutting operations are performed on it.

As

this procedure requires increased air pressure to

inside of the bottle, it must be done before any

cutting operations are performed on it.

Carefully

Carefully

mark out two rings on the pop bottle (about 1

cm apart, near the bit where the sides become

parallel). I have found a convenient way of

doing this by trapping a felt tipped pen in a

drawer and then holding the bottle at either end

whilst rotating it. Cut along the lines with a

pair of scissors. You now have all of the bits

that you will need.

mark out two rings on the pop bottle (about 1

cm apart, near the bit where the sides become

parallel). I have found a convenient way of

doing this by trapping a felt tipped pen in a

drawer and then holding the bottle at either end

whilst rotating it. Cut along the lines with a

pair of scissors. You now have all of the bits

that you will need.

So, to use this

device:

So, to use this

device: